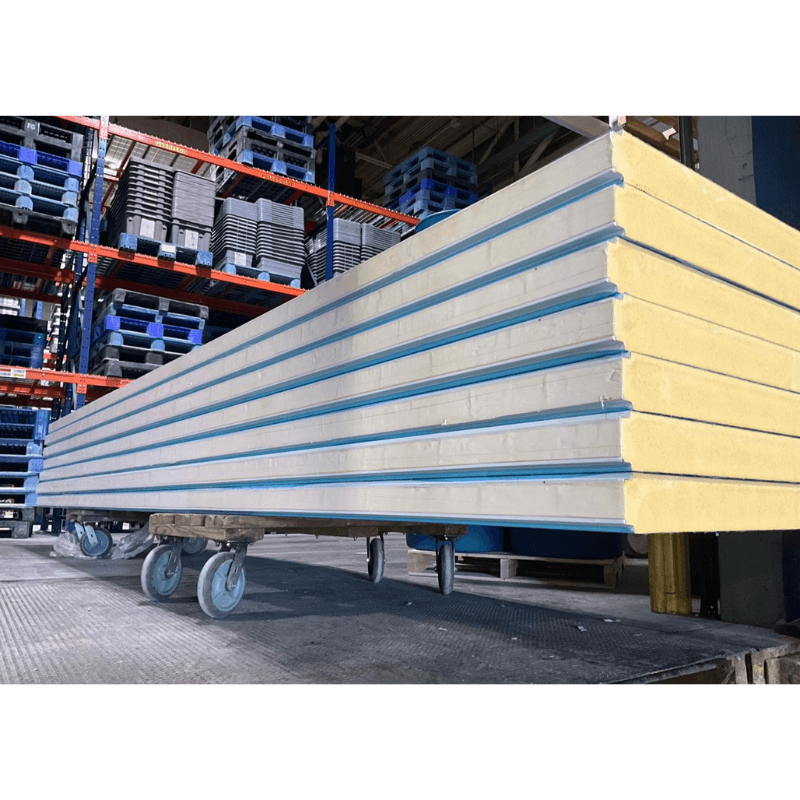

Wharehouse panels

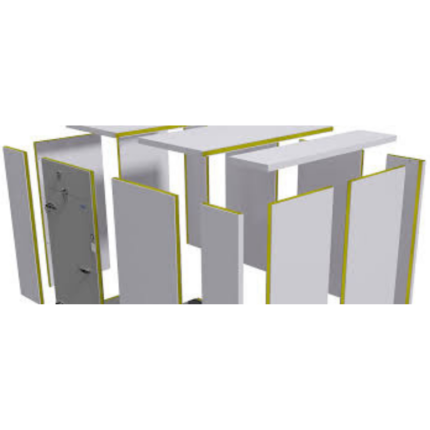

Insulated Metal Panels (IMPs) are premium, high-performance building components engineered to provide exceptional thermal insulation and structural durability. Our cold room sandwich panels feature a rigid polyisocyanurate (PIR) foam core securely bonded between two tough steel facings, delivering outstanding energy efficiency for cooler and freezer applications. Designed with a core thickness starting at 1.6 inches and a minimum foam density of 2.3 pounds per cubic foot (pcf), these panels ensure both thermal stability and structural integrity. Their durable construction makes them perfectly suited for commercial and industrial cold storage environments, helping to maintain consistent temperatures and reduce energy consumption. Built to meet today’s demanding building codes, our custom cold room panels offer a dependable solution for any cold storage project requiring reliable performance, long-term durability, and high thermal efficiency.

- High thermal insulation (suitable for temperatures as low as -4ºF)

- Custom sizes and thicknesses available – made to order to minimize material waste

- Vapor-tight, mechanically strong, and High dimensional stability

- Resistant to harsh or corrosive environments

- Precision-formed edges with tongue-and-groove joints for airtight, moisture-resistant connections

- White lacquered finish for a clean, professional appearance

Ideal For:

Walk-in coolers and freezers, clean rooms, food processing plants, laboratories, and temperature-controlled storage facilities.

Available sizes

| Panel Thickness | Panel Width | Panel Length |

|---|---|---|

| 1.5 in (40 mm) | 39.5 in (1000 mm) | Up to 139 ft (11,900 mm) |

| 2 in (50 mm) | 39.5 in (1000 mm) | Up to 139 ft (11,900 mm) |

| 2.5 in (60 mm) | 39.5 in (1000 mm) | Up to 139 ft (11,900 mm) |

| 3 in (80 mm) | 39.5 in (1000 mm) | Up to 139 ft (11,900 mm) |

| 4 in (100 mm) | 39.5 in (1000 mm) | Up to 139 ft (11,900 mm) |

| 5 in (120 mm) | 39.5 in (1000 mm) | Up to 139 ft (11,900 mm) |

| 6 in (150 mm) | 39.5 in (1000 mm) | Up to 139 ft (11,900 mm) |

Technical Characteristics of Insulated Metal Panels

| Category | Details |

|---|---|

| Exterior Face | • Thickness options: 0.020 in (0.5 mm), 0.024 in (0.6 mm), 0.028 in (0.7 mm) • Material: .G90 galvanized or AZ50 aluminum-zinc coated steel |

| Interior Face | • Thickness options: GAUGE 26 / 24 / 22 • Material: .26 GA and above |

| Coatings | • Polyester 25μm (1 mil) • PVDF 25μm / 35μm (1 mil / 1.38 mils) • Granite HDX / SDP 50 (2.16 mils) |

| Outer Ribbing | • Standard / Flat |

| Inner Ribbing | • Standard / Flat |

| Core Type | • Polyisocyanurate (PIR) |

| Core Density | • 40 Kg/m³ (2.3 PCF) |

| Fire Testing (ASTM E84) | • Flame Spread Index: 20 • Smoke Developed Index: 300 |

| Strength (ASTM E8) | • > 32 ksi steel |

| Functions & Benefits | • Excellent aesthetics • High thermal insulation capacity • High mechanical strength • High dimensional stability • Water vapor tight • Versatile for any configuration • Quick installation & easy maintenance • Easily removable & made to measure (minimizes waste) • Resistant to aggressive environments |

| Panel thickness: |

2” ,3” ,4” ,5” ,6” |

|---|